TP1750

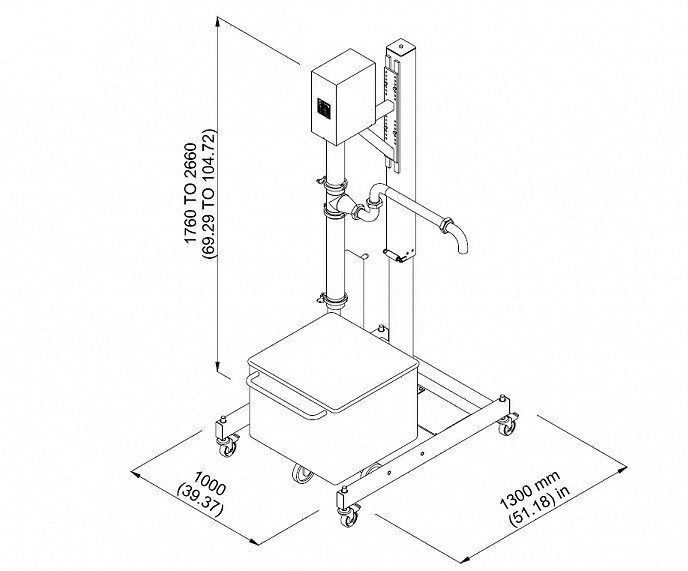

TP1750 Transfer Pump

The new TP1750 transfer pump is built to the same high standards as our proven range of METERITE depositors. Constructed throughout in Stainless Steel. Fully pneumatic in operation and capable of pumping 2.1 tonnes per hour at 20 cycles per minute.

Key Features

Whisper quiet in operation, the TP1750 is built with minimum components for easy strip down and product changeovers.

The unique modular pump mechanism can be fitted with an interchangeable butterfly or lost movement piston depending on product viscosity, allowing delicate food products to flow totally unrestricted.

The Following Products can be Deposited:

- Batters

- Creamed Potato

- Custard

- Sponge Mixes

- Creams

- Grease

- Sauces

- Jelly

- Chocolate Fondant

- Syrups

- Yogurt

- Mayonnaise

- Oils

- Butter

- Pastes

Technical Information

The TP1750 transfer pump is designed to transfer a wide variety of thin or viscous food product materials with temperatures ranging from 5º - 100º Celsius safely and easily.

The TP1750 can be easily adapted to fit customers existing product holding tanks allowing the operator the advantage of taking the TP1750 transfer pump directly to the product source, for example, mixing bowls, holding vessels or cooking kettles, enabling the easy supply of product to depositors on demand, which is usually by means of an auto float level, high/low level probes or indeed ultrasonic detection, thereby enabling a simple but effective method of auto fill.

Specification

Air consumption: 465 litres/min @ 5.5 bar (16 CFM @ 80psi ). Weight: 147kg(323lbs)

Featured Case Study

Doughnut line for Sparks Confectioners

What we did

Our client, part of the Cotswold Food Partnership Family, came to us with two clear objectives.

These were to improve production throughput by increasing running speeds, whilst reducing labour costs.

Contact Us

Please get in touch if you require our services or fill in the form and we will get back to you.

- +44 (0)1482 325651

- [email protected]

- Apple Food Systems

1 Gillett Street

Hull, HU3 4JA

United Kingdom

Latest News

Apple Food Systems is proud to launch its new website which has been designed and built to be easier to use for clients across all platforms,...

Apple Food Systems has the best twelve-month period of business in its history as food producers across the world seek more automated systems...