Easy Fill

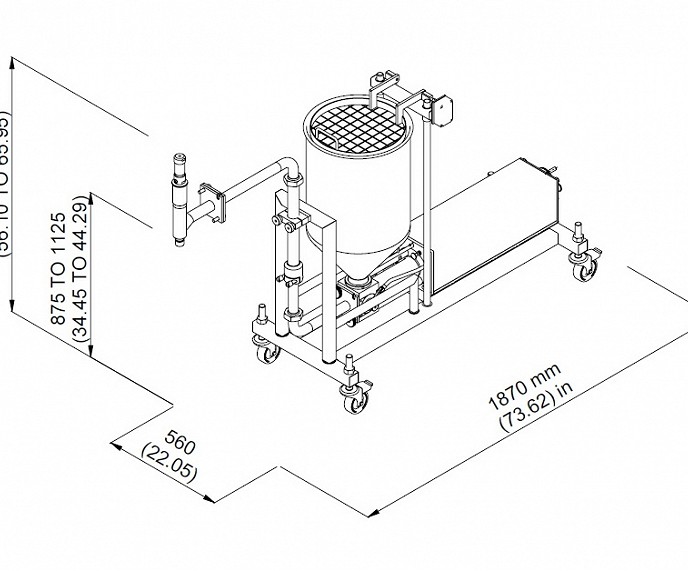

MR900 Low Level Easy Fill

Simplicity is the main feature of the MR900, allowing unskilled operators to easily strip down the machine for cleaning and product change overs.

Key Features

Deposit volume and speed controls can be adjusted in seconds. The MR900 series depositor is pneumatically operated and can be supplied with four sizes of product cylinder. This provides an accurate depositing weight range of 20-1250g, up to 60 cycles per minute.

The machine is extremely robust and is designed to withstand the most demanding conditions with the minimum maintenance. ‘Lubrication free’ pneumatic components can be fitted as an option. The machine shown is fitted with telescopic pipe work as standard allowing the outlet nozzle to be easily positioned exactly were required.

The Following Products can be Deposited:

- Batters

- Creamed Potato

- Custard

- Sponge Mixes

- Creams

- Grease

- Jams

- Sauces

- Jelly

- Chocolate

- Fondant

- Syrups

- Yogurt

- Mayonnaise

- Oils

- Butter

- Pastes

Technical Information

The MR900 depositor can also be mounted on a fixed height stand, a mobile telescopic stand or arranged in a multi-lane configuration upon a height adjustable cantilever frame. Many types of outlet can be supplied, for example: G.P. Outlets for liquids and solids in suspension, Suck-back Outlets fitted with special heads for cake decoration, Rotary spreader outlets to provide full cover spread of material within trays.

Specification

Air consumption: 400 litres/min @ 5.5 bar (14 CFM @ 80psi ). Weight: 110kg(242lbs)

Featured Case Study

Reducing wastage to help US ready meals firm make huge savings

What we did

Our client is one of the largest frozen ready meals producers in the US, making two million meals every day at three manufacturing facilities.

The firm contacted Apple when it wanted to replace one of its depositing machines which was being used to apply gravy and sauces to ready meal trays and was losing significant amounts through lack of accuracy.

Contact Us

Please get in touch if you require our services or fill in the form and we will get back to you.

- +44 (0)1482 325651

- [email protected]

- Apple Food Systems

1 Gillett Street

Hull, HU3 4JA

United Kingdom

Latest News

Apple Food Systems is proud to launch its new website which has been designed and built to be easier to use for clients across all platforms,...

Apple Food Systems has the best twelve-month period of business in its history as food producers across the world seek more automated systems...