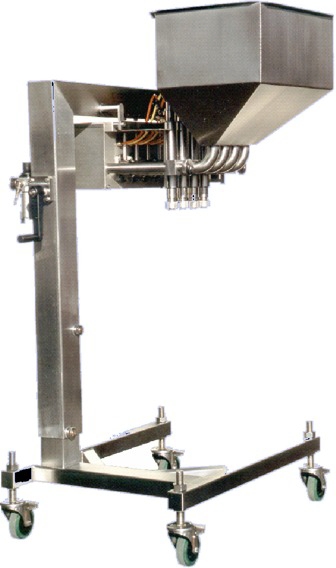

Depositors

Our team is able to provide depositors designed to meet the specific needs of all of our customers, and the demands of automated production in the modern food, cosmetic and pharmaceutical industries.

Crucially, our depositing machines can guarantee accurate weights and operate at a wide range of speed cycles per minute. They are designed not only to withstand the most demanding conditions, but also require the minimum amount of management and maintenance.

If your demands are bespoke then that’s no issue for us, as we pride ourselves on meeting the exacting demands of our customers, whether it be to identify depositors to provide greater weight accuracy and reduce waste, deliver high-speed production, or use specific heads for detailed cake decoration.

Our depositors are easily managed, monitored and maintained, enhancing production efficiency with controls systems able to be adjusted in seconds. They can deposit batters, creamed potato, custard sponge mixes, creams, grease, jams, sauces, jelly, chocolate, fondant, syrups, yogurt mayonnaise, oils, butter, pastes and more.

Offering outstanding accuracy and the highest standards of design to ensure there are less parts to be stripped and cleaned, many of our depositors and transfer pumps are ‘clean in place’ machines, with routine maintenance suitable for semi-skilled operators.

This ensures there is less chance of damage to machine parts in busy and demanding production environments, and crucially quicker turn round times between products to keep production lines running.

What our clients are saying:

Contact Us

Please get in touch if you require our services or fill in the form and we will get back to you.

- +44 (0)1482 325651

- [email protected]

- Apple Food Systems

1 Gillett Street

Hull, HU3 4JA

United Kingdom

Latest News

Apple Food Systems is proud to launch its new website which has been designed and built to be easier to use for clients across all platforms,...

Apple Food Systems has the best twelve-month period of business in its history as food producers across the world seek more automated systems...