Pro Portioner

PRO PORTIONER 20 Depositor/Pump

The “PRO-PORTIONER 20” bench top mounted electronic depositor/injection unit is suitable for use with liquids, creams, gels, sauces and batters even with small particulates, especially for the food, cosmetic and pharmaceutical industries.

Key Features

Outstanding accuracy, superior design & quality with easy to strip/clean components. Automatic or manually controlled via pneumatic palm or foot switch makes the “PRO-PORTIONER 20” especially suited to test kitchens and small to medium sized production facilities. Simply plug into a 220v, Single Phase, 5 amp electrical supply and you’re ready to go (no additional services required).

All types of smooth free flowing products (even with small particulates) can be handled, including batters, aerated cream fillings, chocolate sauces, jams, custards, syrups and gels. The Pro Portioner can be fitted with a wide range of outlets. The outlets can range from a simple tube to a electronically triggered flexible handgun.

The Following Products can be Deposited:

- Batters

- Creamed Potato

- Custard

- Sponge Mixes

- Creams

- Grease

- Jams

- Sauces

- Jelly

- Chocolate

- Fondant

- Syrups

- Yogurt

- Mayonnaise

- Oils

- Butter

- Pastes

Technical Information

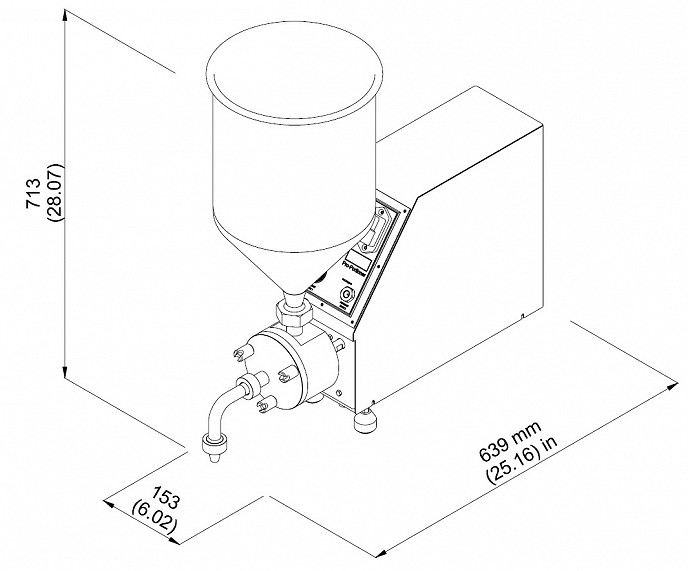

The Pro-Portioner can be used to deposit, fill or inject. Variable operating weight/volume range. Accuracy better than+/- 0.5cc on maximum drop weight. Wide range of quick change deposit nozzle outlets and injection needle sizes available. Speed range infinitely variable. Simple operation via a LCD display and simple select and set procedure. Suitable for inline continuous or batch mixing. Generous 14 litre capacity hopper. Bench mounted small footprint and completely portable. All product contact parts in FDA approved materials. Simple dismantling for ease of cleaning and hygiene.

Specification

Electrical Requirements: 220V 1PH 5A - Weight: 36kg (80lbs)

*Other Electrical Requirements Available

Featured Case Study

What we did

We were consulted by a long standing customer on how to improve throughput as they were in possession of up to 20 of our depositors which were all 20 years old.

Contact Us

Please get in touch if you require our services or fill in the form and we will get back to you.

- +44 (0)1482 325651

- [email protected]

- Apple Food Systems

1 Gillett Street

Hull, HU3 4JA

United Kingdom

Latest News

Apple Food Systems is proud to launch its new website which has been designed and built to be easier to use for clients across all platforms,...

Apple Food Systems has the best twelve-month period of business in its history as food producers across the world seek more automated systems...