About Us

Established in 1985, Apple Food Systems has built a reputation for designing and building bespoke machinery, equipment and processes for the food and pharmaceutical industries which bring major production and savings benefits to business.

We combine traditional values with the latest technology to produce bespoke, robust, sophisticated and cost effective solutions which constantly exceed customers’ expectations.

More than 300 years combined experience

Based in East Yorkshire, we are a family-owned company which boasts a superb and dedicated workforce with more than 300 years’ of combined experience in supplying the highest quality food processing equipment.

Whilst we have moved with the times we have retained our dedication to supplying exactly what is required rather than what is standard, with approximately 60% of goods we produce being bespoke and built to meet exact customer requirements.

Whatever the food, we've the solution

We are a world leader in manufacture of bespoke bakery depositors, food processing equipment, filling and decorating systems and highly-efficient production lines.

We design, manufacture, install and maintain depositors, transfer pumps, volumetric fillers, cake decorating systems, automated cake lines, multi-head depositors and bespoke food processing systems.

Apple machinery can be designed to deposit most moisture bearing foods including batters, sponge mixes, jams, chocolate sauce and chocolate butter, creams, sauces, fondant, mayonnaise, Christmas pudding mix and even cold mashed potato!

Bringing you efficiency, speed & savings

At Apple Food Systems we have helped many businesses make huge improvements to quality, speed, efficiency and hygiene control in food production.

Our bespoke systems and production lines can greatly reduce manual labour and operation, bringing down costs associated with manual labour and error, increasing throughput, reducing hand contact of products and lessening waste.

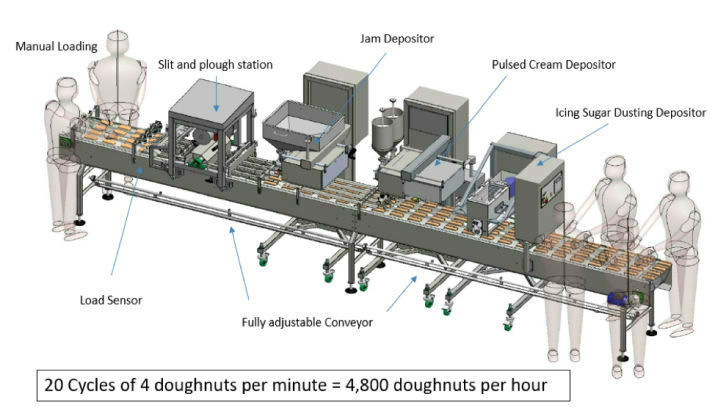

As can be seen from the image below, on this production line of donuts for a client, we reduced the manual input from 16 to just 4 people, producing 4,800 doughnuts per hour.

An investment in a production line like this can bring a return on investment within 12 to 18 months.

Doughnut Finger production line example

Ask about our ‘Clean In Place’ (CIP) Products

Many of our products are ‘Clean In Place’ (CIP) designed, ensuring minimum downtime between the manufacture of differing food products and significantly reducing the amount of times productions lines are not running.

These systems are completely flush cleaned after each production cycle, including all nozzles, reducing the need for them to be taken off the line and taken to a dedicated cleaning rooms before running a new product through the production process.

What our clients are saying:

Contact Us

Please get in touch if you require our services or fill in the form and we will get back to you.

- +44 (0)1482 325651

- [email protected]

- Apple Food Systems

1 Gillett Street

Hull, HU3 4JA

United Kingdom

Latest News

Apple Food Systems is proud to launch its new website which has been designed and built to be easier to use for clients across all platforms,...

Apple Food Systems has the best twelve-month period of business in its history as food producers across the world seek more automated systems...